The production of sanitary napkins involves a variety of raw materials, each selected for its specific properties and benefits. The primary components typically include absorbent materials, non-woven fabrics, adhesives, and additional features such as anion technology.

One of the most common absorbent materials used in sanitary napkins is cellulose, derived from wood pulp. Cellulose is favored for its high absorbency, allowing it to retain moisture effectively. Studies indicate that cellulose can absorb up to 20 times its weight in liquid, making it an ideal choice for feminine hygiene products.

In addition to cellulose, superabsorbent polymers (SAP) are often incorporated into the design of sanitary napkins. SAPs can absorb and retain large volumes of liquid, enhancing the overall absorbency of the product. Research shows that these polymers can absorb up to 300 times their weight in fluid, providing a significant advantage in terms of leakage protection.

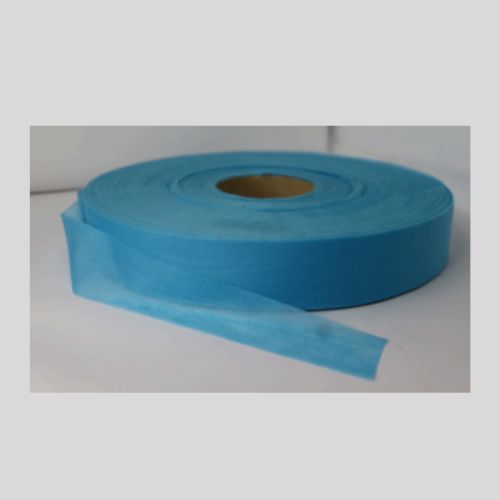

The outer layer of sanitary napkins is typically made from non-woven fabrics, which are engineered for softness and breathability. These fabrics are often composed of polypropylene or polyethylene, which are synthetic materials known for their durability and moisture-wicking properties. The use of non-woven fabrics can improve comfort and reduce the risk of skin irritation.

Adhesives play a critical role in ensuring that sanitary napkins remain securely in place during use. Hot melt adhesives are commonly used due to their strong bonding properties and quick-setting capabilities. These adhesives are designed to withstand moisture and maintain their integrity throughout the duration of wear.

Recent advancements in technology have led to the incorporation of anion technology in some sanitary napkin products. Anions are negatively charged ions that are believed to neutralize odors and promote a balanced pH level. This technology is gaining attention for its potential health benefits, as maintaining a balanced pH is crucial for preventing infections and promoting overall feminine health.

In conclusion, the raw materials used in the production of sanitary napkins are selected based on their absorbent capabilities, comfort, and safety. The combination of cellulose, superabsorbent polymers, non-woven fabrics, and innovative technologies such as anion technology contributes to the effectiveness and user experience of these essential hygiene products. Understanding these materials can provide consumers with valuable insights into the quality and functionality of the products they choose.

The story of Ami Care Products

Here is the story of Amicare Products

From Compassion to Care – The Story of Ami Care

It all started with a simple yet powerful idea – to create products that truly care for women’s health and comfort. Inspired by her own experiences and the struggles faced by countless women, Amirtha Shree envisioned a brand that goes beyond just products – one that brings dignity, awareness, and wellness to every woman’s life. Ami Care was born from her passion to make a difference, combining empathy, innovation, and quality to support women at every stage. Join us as we share the journey of how Ami care came to life and how one woman’s dream is empowering women everywhere.

Founder Amirtha Shree with visionary Businessman Mr. Maharaja

Social Commitment

We are committed to improving menstrual health and hygiene by providing affordable and accessible products, spreading awareness to break taboos, and supporting women’s empowerment. It also works towards eco-friendly solutions for safe disposal and sustainability, while partnering with communities, NGOs, and governments to ensure dignity, health, and equality for women.

Passion

Our passion is to ensure every woman lives with dignity and confidence—by making menstrual care accessible, breaking taboos, empowering women, and protecting our planet with sustainable solutions.

Responsibility

As a sanitary napkin company, our responsibility extends beyond manufacturing. We are dedicated to making menstrual hygiene affordable and accessible, creating awareness to break social taboos, and empowering women through education and employment opportunities. We also carry the responsibility of protecting the environment by promoting safe disposal and developing sustainable, eco-friendly solutions. Our goal is to contribute to healthier lives, greater dignity, and a more equitable society.